Rubber Pipe Expansion Joint Flanged Ends

Basic Info

Model No.: DN32-DN600

Product Description

Model NO.: DN32-DN600 Transport Package: by Wood Pallet or as Per Your Requirement Origin: China Trademark: SC Specification: SGS Single Spherical Rubber Expansion Joint

Introductions:

Rubber Expansion Joint is used to provides stress relief in piping systems due to thermal dilatation, mechanical and other movements. It provides flexibility and concurrent movements,isolation of vibration and noise, resistance to abrasion and chemical erosion. They are widely used in water treatment,chemical industry,building system,Shipping ... ect

Features & Benefits

Absorbs noise and vibration

General Rubber Expansion Joint effectively dampen and insulate against the transmission of nosie and vibration caused by mechanical equipment.

Higher Burst Strength

Spherical molding design expansion joint with strong chemical fibres made it can be withstand more bursting pressure of over 5.0Bar and a maximum operating pressure of 2.5Mpa.

Absorbs Directional Movement

The temperature changes in piping system can effect thermal movement, rubber expansion joint allow for axial compression & extension,lateral deflection,also angular and torsional movement to settle the problem.

Stress Relief

Expansion Joint can deal with pipe stress caused by thermal expansion/contraction or foundation settlement.

Compensates for Slight Misalignment

Rubber Expansion Joints are commonly used for slight pipe misalignment during installation of both new construction & replacement applications.

Miscellaneous Synthetic Elastoer

A wide variety of elastomers are available to meet specific demands of industria applications.

Application:

Water Treatment

Production and distribution of drinking water,waste water treatment & pumping installations

Building system

Central heating and air conditioning systems,hot and cold water systems.

Shipping building

Cooling systems for Machines,sanitary utilities,fire fighting systems and various loading & unloading systems.

Precess Industry

Process piping in paper,pulp,chemical,primary metal & petroleum refining plants.

Chemical Industry

Fluids handling systems:

Acids bases,hydrocarbons,emulsions, solutions,air,gas steam,water etc.

Metallurgy

Blast furnace gas,compressed air and industrial water systems.

Food industry

Drinking water and other beverage handling systems.

Features

Minimal axial diamensions

Low warping forces

High0resistance to work

High-capacity acoustic dampimng

Material Specification:

Other rubber material such as Nitrile,hypalon, NR etc, also available on request.

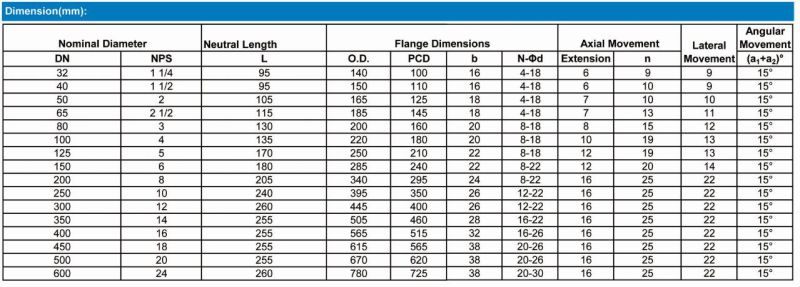

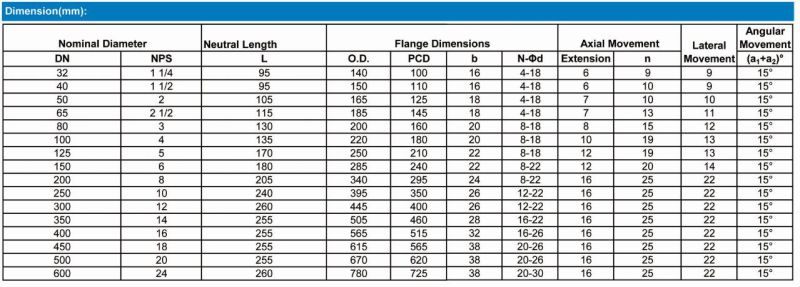

Technical Informations

Company Profile:

Our Own Factory and 50 Partner Factories Increase Your Selection valves, Pipe Fittings and machined parts all in one place.

You source a lot of pipeline products and machined parts from China. So wouldn't it be nice if your supplier had more than just one of the products you need? With our own factory and 50 partner factories, we can help you conveniently source items from one place. We can direct your requests for ball, gate, check, butterfly and Globe Valves, scrwed and butt-welded pipe fittings, forged, cast and machined parts in materaisl of iron, steel, stainless steel etc, to right factory. All of our products meet API, ANSI, DIN, BS, JIS, ISO, MSS SP and AWWA etc,

Everyone on our QC staff goes through an intensive training program that covers raw material testing and final product examination, including its packaging, and we have 50 senior R&D engineers ready to handle your OEM requests, samples within 3 to 30 days. E-mail us today to learn more.

Production Line:

Drawings→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product check→ packing →delivery. Contact us if you need more details on Single Spherical Rubber Expansion Joint. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rubber Expansion Joint、Expansion Joint. If these products fail to match your need, please contact us and we would like to provide relevant information.

Introductions:

Rubber Expansion Joint is used to provides stress relief in piping systems due to thermal dilatation, mechanical and other movements. It provides flexibility and concurrent movements,isolation of vibration and noise, resistance to abrasion and chemical erosion. They are widely used in water treatment,chemical industry,building system,Shipping ... ect

Features & Benefits

Absorbs noise and vibration

General Rubber Expansion Joint effectively dampen and insulate against the transmission of nosie and vibration caused by mechanical equipment.

Higher Burst Strength

Spherical molding design expansion joint with strong chemical fibres made it can be withstand more bursting pressure of over 5.0Bar and a maximum operating pressure of 2.5Mpa.

Absorbs Directional Movement

The temperature changes in piping system can effect thermal movement, rubber expansion joint allow for axial compression & extension,lateral deflection,also angular and torsional movement to settle the problem.

Stress Relief

Expansion Joint can deal with pipe stress caused by thermal expansion/contraction or foundation settlement.

Compensates for Slight Misalignment

Rubber Expansion Joints are commonly used for slight pipe misalignment during installation of both new construction & replacement applications.

Miscellaneous Synthetic Elastoer

A wide variety of elastomers are available to meet specific demands of industria applications.

Application:

Water Treatment

Production and distribution of drinking water,waste water treatment & pumping installations

Building system

Central heating and air conditioning systems,hot and cold water systems.

Shipping building

Cooling systems for Machines,sanitary utilities,fire fighting systems and various loading & unloading systems.

Precess Industry

Process piping in paper,pulp,chemical,primary metal & petroleum refining plants.

Chemical Industry

Fluids handling systems:

Acids bases,hydrocarbons,emulsions, solutions,air,gas steam,water etc.

Metallurgy

Blast furnace gas,compressed air and industrial water systems.

Food industry

Drinking water and other beverage handling systems.

Features

Minimal axial diamensions

Low warping forces

High0resistance to work

High-capacity acoustic dampimng

Material Specification:

| Item No. | Parts Name | Material |

| 1 | Cover | EPDM |

| 2 | Fabric | Nylon |

| 3 | Tube | EPDM |

| 4 | Retain Ring | Steel |

| 5 | Flange | Carbon Steel |

Technical Informations

| Working pressure (Bar) | 10bar | 16bar | 25bar |

| Burst Pressure (Bar) | 30bar | 48bar | 55bar |

| Vacuum (mmHg) | 400 | 650 | 750 |

| Suitable Temperature (ºC) | NR | '-15ºC ~ 115ºC |

| EPDM | '-30ºC ~ 170ºC | |

| NBR | 15ºC~140ºC | |

| Silicon | 130ºC ~ 250ºC | |

| Applicable Medium | Water,sea water,steam,oil,acid,alkali,and so on. | |

Company Profile:

Our Own Factory and 50 Partner Factories Increase Your Selection valves, Pipe Fittings and machined parts all in one place.

You source a lot of pipeline products and machined parts from China. So wouldn't it be nice if your supplier had more than just one of the products you need? With our own factory and 50 partner factories, we can help you conveniently source items from one place. We can direct your requests for ball, gate, check, butterfly and Globe Valves, scrwed and butt-welded pipe fittings, forged, cast and machined parts in materaisl of iron, steel, stainless steel etc, to right factory. All of our products meet API, ANSI, DIN, BS, JIS, ISO, MSS SP and AWWA etc,

Everyone on our QC staff goes through an intensive training program that covers raw material testing and final product examination, including its packaging, and we have 50 senior R&D engineers ready to handle your OEM requests, samples within 3 to 30 days. E-mail us today to learn more.

Production Line:

Drawings→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product check→ packing →delivery. Contact us if you need more details on Single Spherical Rubber Expansion Joint. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rubber Expansion Joint、Expansion Joint. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Ductile Iron Pipe Fittings

Premium Related Products

Other Products

Hot Products

Rotary Vane Wet Water MeterBrass Ball ValveBs750 Fire HydrantFlanged Rubber Expansion Joint, DINDIN Cast Iron Ball Valve Pn10-16Cast Iron Swing Check Valve200X Ductilr Iorn Pressure Reducing ValveAir ValveWafer Lug Type Butterfly Valve, Lever OperatorDuctile Iron Pipe CouplingHot Sale Grooved End Pipeline ConnectionSteel Pipe Merchant Coupling for Pipe LineStainless Steel Pipe Fittings (SS Pipe Fittings)Din3352-F4/F5 Resilient Seated Gate Valve Flanged End Non Rising StemDuctile Iron PE/PVC Quick Flange AdaptorSs Cr1 Repair Clamp